Variable Rate MAP Case Study

Phosphorus is a key nutrient for crop production. With this knowledge, growers have consistently applied relatively robust rates of starter fertiliser (e.g. MAP) at sowing to ensure that crops are not P-limited. The blanket application of Phosphorus fertiliser overtime, has in some cases, resulted in an accumulation of available Phosphorus. This has typically occurred in under-performing areas of paddocks, where P-removal has been low. Conversely, in some over-performing areas of paddocks where P-removal is high, a reduction in available Phosphorus has occurred. Ultimately, the variability in crop yield across a paddock, will overtime create spatial variability in the amount of available Phosphorus. As a result, growers who have the capacity to apply Phosphorus on a variable-rate basis, are able to take advantage of this variability, by strategically applying fertiliser spatially. This allows the appropriate fertiliser rate to be applied to the desired location within a paddock.

Where both mechanically possible and agronomically correct to do so, variable rate Phosphorus should be considered to better match the inputs to the outputs in a cropping system. A key step in achieving variable-rate applications includes the production of a prescription. There are many methods that can be used to produce a variable-rate Phosphorus prescription, an example of one such method is the focus of this article.

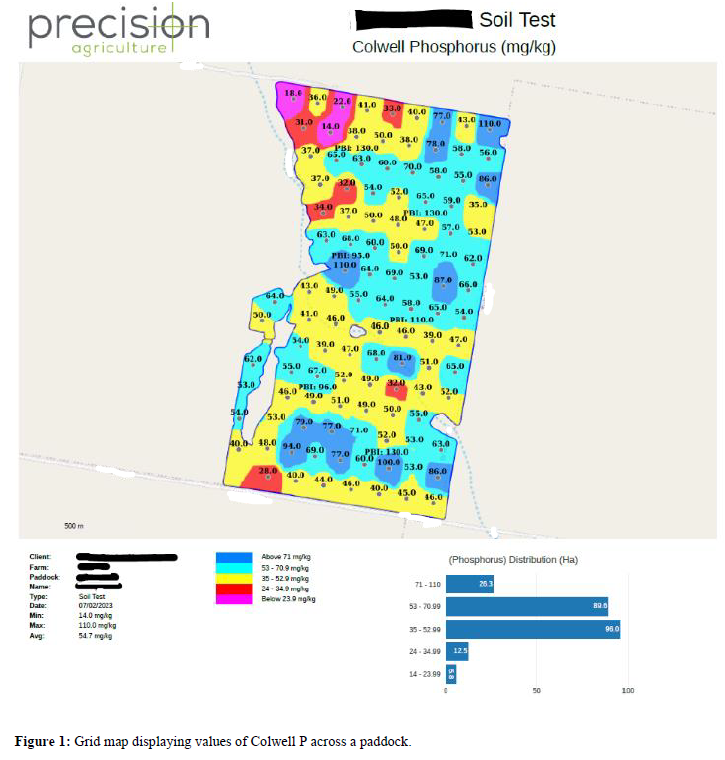

The following example is based on a paddock which has a recent history of continuous cropping and was sown to canola in 2023. At the beginning of 2023, the paddock was grid sampled and tested for various soil characteristics by Precision Agriculture. One characteristic that showed major variability included Phosphorus (Figure 1). In turn, it was decided that applying MAP on a variable-rate basis would be more efficient than the blanket 70 kg/ha which was originally programmed. To achieve this, a variable-rate MAP prescription was produced by splitting the paddock into three ‘Zones’.

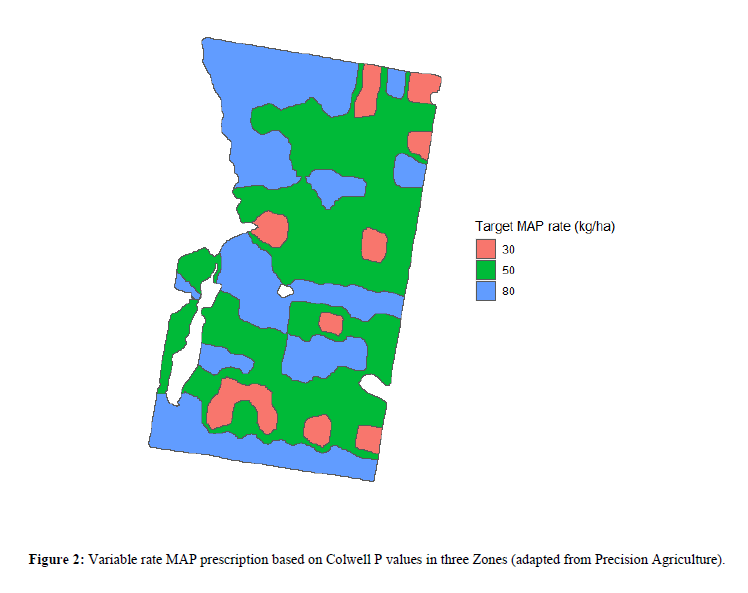

Zone 1 (Lower than ideal Colwell P) – There were likely some P-limited areas in this Zone which required a ‘building’ of available Phosphorus.

Zone 2 (Higher than necessary but not excessive Colwell P) – It was unlikely that there were P-limited areas in this Zone as the range of Colwell P values was above the critical concentration of Phosphorus for canola (approx. 30-40 mg/kg). In turn, this area was considered one where ‘mining’ of P was to occur.

Zone 3 (Much higher than required Colwell P) – This was considered another area where ‘mining’ of P was to occur.

Rates of MAP were then assigned to each zone based on the range of Colwell P values in each zone relative to the critical concentration of Phosphorus for canola (Figure 2), plus utilising the MAP that the grower had already ordered. The overall aim of this prescription was to begin to even out variability in Phosphorus across the paddock.

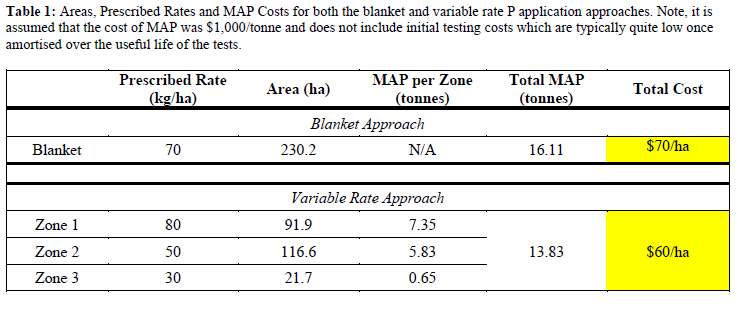

By attempting to even out the spatial variability in available Phosphorus, the grower in this example was able to make reductions in expenditure on MAP. An example of the cost saving is shown in the table below (Table 1). Table 1 breaks down the prescribed rates, areas and total cost of both the blanket and variable rate methods (assuming that the cost of MAP was $1,000/tonne). As demonstrated, the variable rate approach saved the grower approximately $10/ha across the paddock in question.

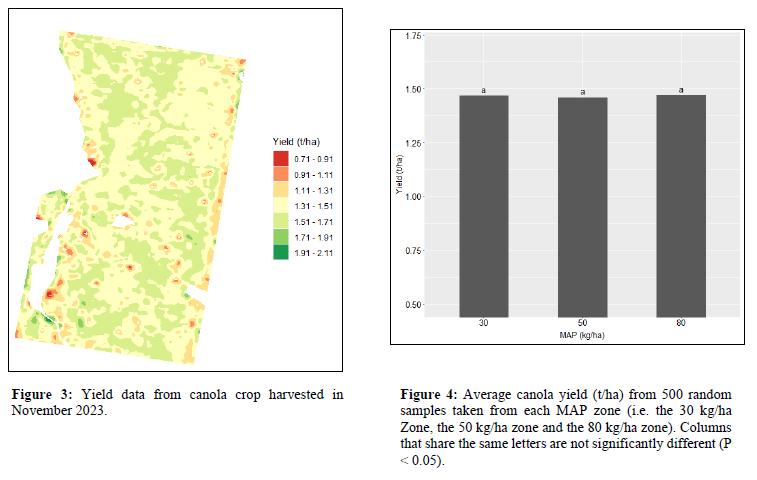

Importantly, the reduction in MAP input in some zones had no clear impact on yield. This became evident after observing no clear visual trends in the yield map of the 2023 harvest (Figure 3) and no statistically significant difference in yield between the three MAP rates (Figure 4).

Although a cost saving was made using the method presented in this case study, it is just one of many methods that could be undertaken to apply Phosphorus fertiliser on a variable rate basis. Factors such as soil type, cost of soil sampling and availability of historic spatial data such as yield data, should be considered when determining how the variable rate prescription should be derived, or whether it should be derived at all.

If there is a reasonable case for the implementation of a variable-rate Phosphorus prescription, it will likely need to be executed over multiple years to reduce spatial variability, or rectified in a one off operation spreading MAP or manure. Once spatial uniformity is achieved, applications of Phosphorus fertiliser should be made on a replacement basis derived from yield data. Follow-up soil testing would be required to ensure that uniformity in available Phosphorus is maintained across the paddock.

In summary, the application of variable rate Phosphorus in an agronomically sound manner can have great implications for the efficiency of the farming system and ultimately improve the bottom line.